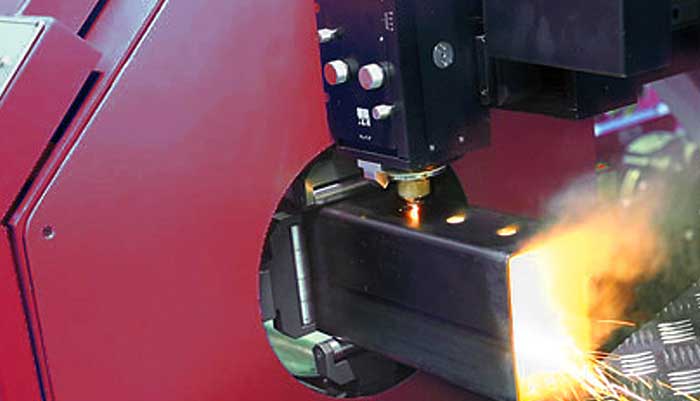

Tube Laser Cutting Systems 300w

StarCut Tube Laser SL is the best laser cutting system for complex medical devices, such as stents and aortic valve replacements.

StarFiber Series includes compact fiber lasers and optional focusing heads to allow for cutting or laser welding. SmartWeld(tm), a technology that allows for fine and large welds, can also be used.